Boost commercial laundry profitability with RFID technology

Learn how RFID solutions eliminate inefficiencies, improve tracking accuracy, and optimise operational workflows for high-volume laundry businesses.

Boost commercial laundry profitability with RFID technology

Learn how RFID solutions eliminate inefficiencies, improve tracking accuracy, and optimise operational workflows for high-volume laundry businesses.

Managing a commercial laundry involves juggling thousands of linens, strict turnaround times, and high-quality standards. RFID technology is transforming this process for laundry managers and owners by automating tracking and data capture at each stage. The result is smoother workflows—from sorting soiled items to delivering clean linens—with fewer errors, lower costs, and improved efficiency. Below, we explore how RFID technology streamlines operations step by step and how it compares to traditional methods like barcodes in keeping your laundry running at peak performance.

Managing a commercial laundry involves juggling thousands of linens, strict turnaround times, and high-quality standards. RFID technology is transforming this process for laundry managers and owners by automating tracking and data capture at each stage. The result is smoother workflows—from sorting soiled items to delivering clean linens—with fewer errors, lower costs, and improved efficiency. Below, we explore how RFID technology streamlines operations step by step and how it compares to traditional methods like barcodes in keeping your laundry running at peak performance.

How RFID technology enhances commercial laundry efficiency

Faster sorting and check-in

When soiled linens and garments arrive at your commercial laundry, RFID readers installed strategically can instantly scan hundreds of items in one go, logging each piece into the system without manual counting. No line-of-sight is needed—tags can be read inside bags or bins, so staff don’t have to unpack and individually handle every item. This speeds up the check-in process dramatically, minimising human resources to sort through dirty laundry by hand. Items can be immediately sorted by client or linen type as the system identifies them, improving accuracy and saving labour. This efficiency can improve profits.

Optimised washing and processing

RFID technology continues to add value once items move to the wash. Because each tag carries a unique ID, the system knows exactly which items are in each wash cycle. This ensures no piece is left behind or misrouted—if a tagged item isn’t detected moving to the next stage, staff are alerted to check the machine. The tags themselves are built to endure industrial laundry conditions (high heat, water, chemicals), so they keep working through repeated wash and dry cycles. Additionally, RFID data can trigger special handling for certain pieces, ensuring that items requiring extra sanitisation receive the correct treatment.

Real-time tracking and inventory management

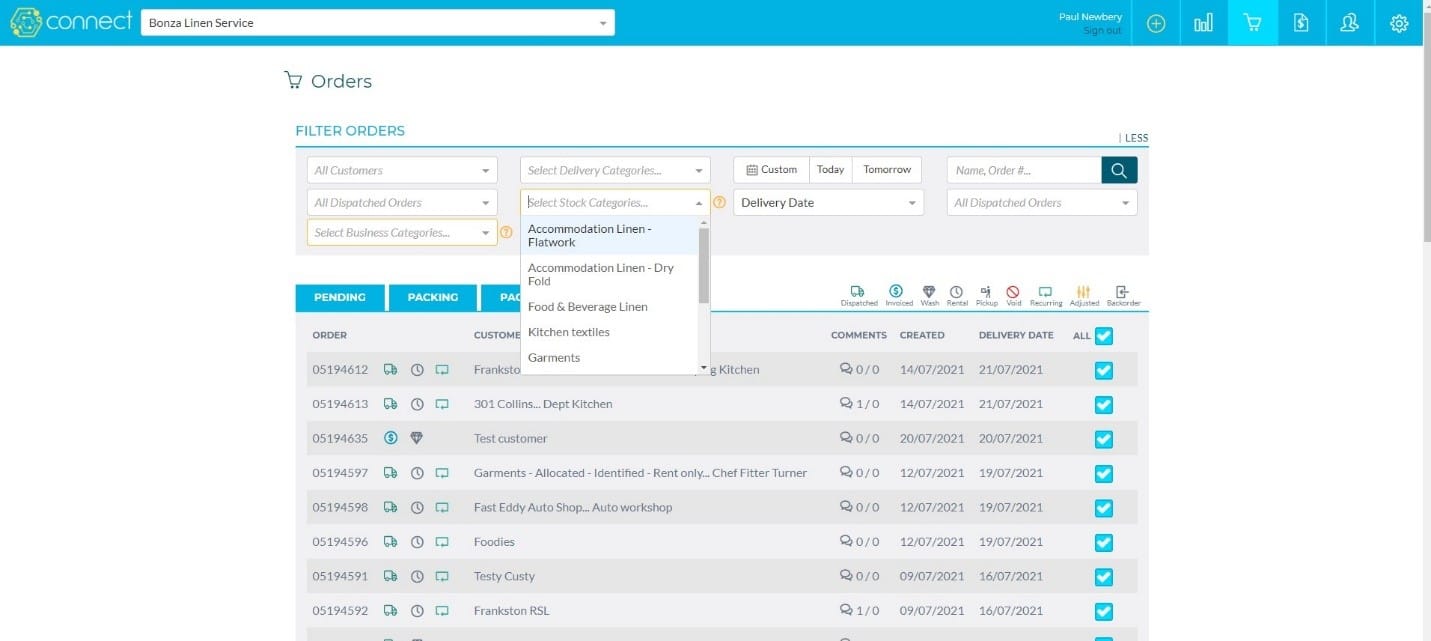

After washing, RFID tags help orchestrate the sorting, folding, and packing of clean linens. Staff or automated sorters use RFID readers to quickly verify each item and direct it to the right cart or customer order, preventing mix-ups. Every movement is recorded in real-time—managers can see exactly how many items of each type are in progress, in storage, or en route to clients. With RFID, inventory counts that once took hours can be done in minutes. This real-time visibility means missing items are noticed immediately and investigated before they become losses, significantly reducing linen replacement costs.

Enhanced efficiency and productivity

By automating certain tasks, staff are freed from repetitive manual tasks and can focus on quality control and service. This means the same team can handle a larger volume of laundry in less time. Turnaround times improve because bottlenecks—such as slow manual sorting or inventory reconciliation—are removed. Many facilities report productivity increases of around 25% and operational cost reductions near 30% thanks to streamlined workflows. Faster processing and fewer errors also lead to better service for clients, ensuring that hotels, hospitals, and other businesses receive their linens quickly and correctly.

Boost the efficiency and profitability of your laundry operations with advanced RFID solutions

Implementing RFID tech brings automation and data-driven decision-making into commercial laundry management. At Bundle Laundry, our laundry asset management system integrates RFID tech to enhance efficiency, track inventory in real-time, and reduce losses. Our end-to-end solutions streamline workflows, ensuring a seamless, cost-effective operation.

From automating sorting and washing to providing detailed analytics on linen usage and lifecycle tracking, RFID solutions help laundry operators make informed decisions that boost profitability. By minimising errors, reducing costs, and improving inventory accuracy, RFID tech provides a measurable return on investment.

Implementing RFID tech brings automation and data-driven decision-making into commercial laundry management. At Bundle Laundry, our laundry asset management system integrates RFID tech to enhance efficiency, track inventory in real-time, and reduce losses. Our end-to-end solutions streamline workflows, ensuring a seamless, cost-effective operation.

From automating sorting and washing to providing detailed analytics on linen usage and lifecycle tracking, RFID solutions help laundry operators make informed decisions that boost profitability. By minimising errors, reducing costs, and improving inventory accuracy, RFID tech provides a measurable return on investment.

Client success stories

"The transition to Bundle has been instrumental in Allied Laundry continuing to drive change and business improvement by providing real-time customer ordering information, streamlined ordering, and billing processes and have enabled a considerable reduction in staff time. The system has been a real success story for Allied Laundry."

Mark Mabbet

Allied Laundry Service

"No question is a stupid question in the eyes of the Bundle team. Their customer service, expertise and knowledge ensured a smooth transition for me when I purchased my business. The system is user friendly and easy to navigate, while syncing seamlessly with my accounts package."

Geraldine Minogue

Associated Laundry Services

Since the transition from a manual, paper-driven system to Bundle, the time spent managing orders through to invoicing has been reduced by some 75%. From an administrative perspective, it is far easier to track the progress of orders, respond to queries (and resupply dockets).

The management abilities for individual account needs with set days, recurring orders, fixing cut-off times, adding notes to orders and pick-ups means that all relevant persons have the same information.

Customer support is also given a high priority and queries and concerns are met promply and efficiently.

Cynthia Hertrick

Blueline Laundry

Discover the benefits of RFID tech in commercial laundry

Find out how RFID-enabled solutions can transform your laundry operations, enhance asset visibility, and drive greater profitability.

FAQs

Yes. By preventing lost inventory, reducing manual labour, and streamlining tracking processes, RFID lowers expenses and improves overall profitability.

Unlike barcodes, RFID tech enables bulk scanning without the need for line-of-sight, allowing faster processing. It also withstands industrial laundry conditions, providing long-term durability and reliability.

Absolutely. While RFID tech is highly effective in large operations, it can also scale to meet the needs of smaller laundries, helping them optimise efficiency and asset management without excessive overhead costs.