Discover the key challenges of using a traditional laundry sorting system that can be solved with RFID asset tracking

The integration of Radio Frequency Identification technology into linen asset tracking has revolutionised the way laundry operations are managed. Explore why this technology is at the core of establishing an efficient laundry sorting system.

Discover the key challenges of using a traditional laundry sorting system that can be solved with RFID asset tracking

The integration of Radio Frequency Identification technology into linen asset tracking has revolutionised the way laundry operations are managed. Explore why this technology is at the core of establishing an efficient laundry sorting system.

In industries where high volumes of linens are used daily—like healthcare, hospitality, linen rental, and even food service—efficient linen management can directly impact both operational costs and service quality.

With millions of linens needing to be cleaned, sorted, and redistributed on time, manual processes become increasingly unreliable. This is where RFID (Radio Frequency Identification) linen asset tracking has stepped in as a technological game changer. RFID technology, when applied to linen asset management, transforms what could otherwise be a labour-intensive, error-prone system into one that is streamlined, accurate, and scalable.

Read on to explore what challenges in a traditional laundry sorting system can be overcome effortlessly with RFID linen asset tracking to reduce errors, improve efficiency, and enable data-driven decisions.

In industries where high volumes of linens are used daily—like healthcare, hospitality, linen rental, and even food service—efficient linen management can directly impact both operational costs and service quality.

With millions of linens needing to be cleaned, sorted, and redistributed on time, manual processes become increasingly unreliable. This is where RFID (Radio Frequency Identification) linen asset tracking has stepped in as a technological game changer. RFID technology, when applied to linen asset management, transforms what could otherwise be a labour-intensive, error-prone system into one that is streamlined, accurate, and scalable.

Read on to explore what challenges in a traditional laundry sorting system can be overcome effortlessly with RFID linen asset tracking to reduce errors, improve efficiency, and enable data-driven decisions.

The main challenges of using a traditional laundry sorting system

Laundry sorting for large-scale operations presents a logistical challenge, especially when it’s done manually. Without RFID, many businesses rely on physical labels, barcodes, or even handwritten tags to track their linen inventory. These manual processes, while familiar, often result in human errors and operational inefficiencies. Some common challenges in traditional systems include:

Lost or misplaced linens:

It’s common for items to go missing when manual handling and counting are involved in the sorting process. Linens may get lost in transit, misplaced in storage, or even accidentally discarded.

Inconsistent inventory counts:

Without real-time tracking, keeping an accurate inventory of linens can be a daunting task. Over time, the inaccuracies build up, leading to excess ordering or running out of stock.

Human error:

Sorting linens by hand leads to mistakes. Misclassifying linens can affect productivity and customer satisfaction, particularly in industries like healthcare where specific linen types serve different purposes.

Time-intensive processes:

Sorting by hand or relying on codes to scan each individual item is slow, inefficient, and prone to bottlenecks. This translates into higher labour costs and potential delays in service.

The inefficiencies in traditional sorting systems ultimately translate into increased costs, reduced productivity, and customer dissatisfaction. RFID linen tracking directly addresses these issues, creating a more dependable system for laundry sorting.

Bundle Track enhances laundry productivity and linen management

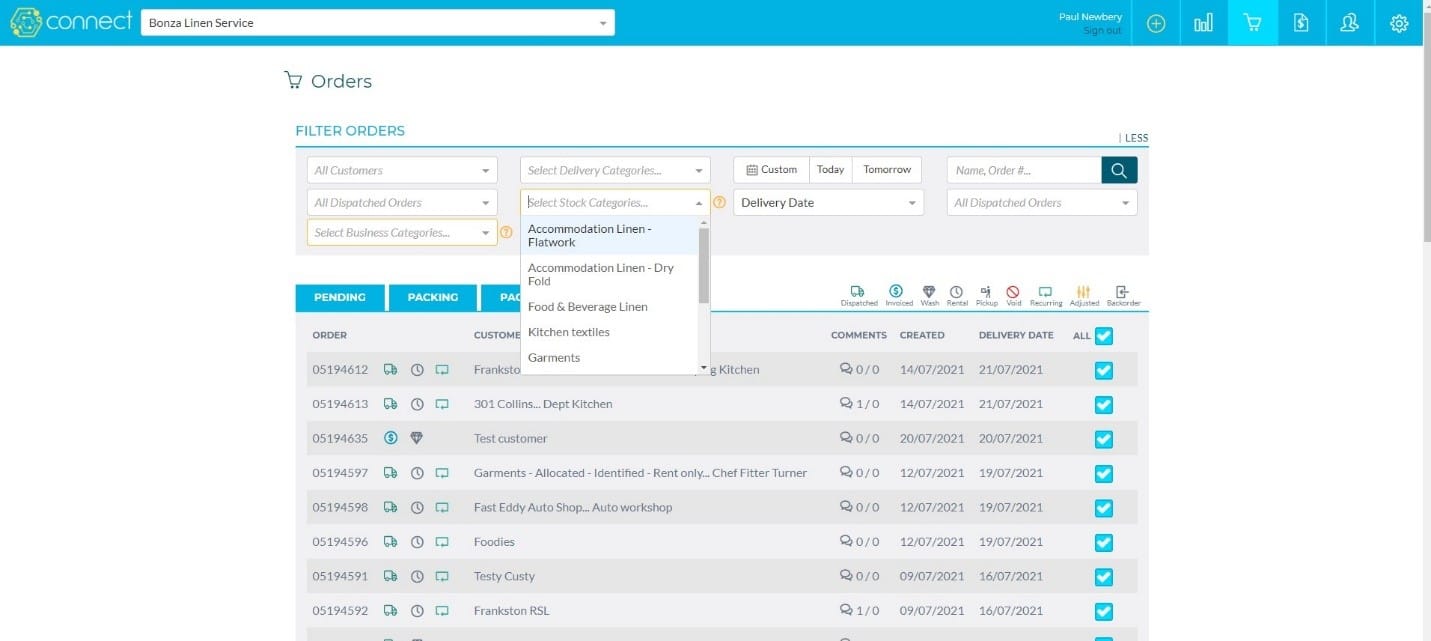

Bundle Track is a revolutionary laundry asset management system that can help businesses improve their linen management pipeline by simplifying and streamlining processes.

With its cloud capabilities, it can read information transmitted from an RFID chip embedded in a linen cloth. Information can be relayed from the software about a linen item’s location in real-time, decreasing incidents of lost items due to theft or misplacement.

This system can significantly reduce a business’s expenditure needed to replace lost items. Its user-friendly features make it easy for employees to monitor linen utilisation and track linen inventory statuses. With Bundle Track, businesses can maximise their cost-saving measures, boost workforce productivity, and improve overall ROI.

Bundle Track is a revolutionary laundry asset management system that can help businesses improve their linen management pipeline by simplifying and streamlining processes.

With its cloud capabilities, it can read information transmitted from an RFID chip embedded in a linen cloth. Information can be relayed from the software about a linen item’s location in real-time, decreasing incidents of lost items due to theft or misplacement.

This system can significantly reduce a business’s expenditure needed to replace lost items. Its user-friendly features make it easy for employees to monitor linen utilisation and track linen inventory statuses. With Bundle Track, businesses can maximise their cost-saving measures, boost workforce productivity, and improve overall ROI.

Client success stories

"The transition to Bundle has been instrumental in Allied Laundry continuing to drive change and business improvement by providing real-time customer ordering information, streamlined ordering, and billing processes and have enabled a considerable reduction in staff time. The system has been a real success story for Allied Laundry."

Mark Mabbet

Allied Laundry Service

"No question is a stupid question in the eyes of the Bundle team. Their customer service, expertise and knowledge ensured a smooth transition for me when I purchased my business. The system is user friendly and easy to navigate, while syncing seamlessly with my accounts package."

Geraldine Minogue

Associated Laundry Services

Since the transition from a manual, paper-driven system to Bundle, the time spent managing orders through to invoicing has been reduced by some 75%. From an administrative perspective, it is far easier to track the progress of orders, respond to queries (and resupply dockets).

The management abilities for individual account needs with set days, recurring orders, fixing cut-off times, adding notes to orders and pick-ups means that all relevant persons have the same information.

Customer support is also given a high priority and queries and concerns are met promply and efficiently.

Cynthia Hertrick

Blueline Laundry

Book a demo

Boost linen management efficiency and the productivity of laundry operations with Bundle Track.

Get in touch with us to book a demo.

FAQs

The best way of organising laundry processes and linen items can vary from business to business, consulting an operational specialist can deliver vital insights for businesses in this area.

RFID asset tracking transforms systems for laundry sorting with the following:

- Automation to minimise errors

- Real-time tracking and inventory management

- Enhanced sorting accuracy and efficiency

- Optimised linen utilisation and lifespan