Warning signs that your laundry equipment may be headed for a breakdown

Here are clues that your laundry equipment is due for maintenance and how laundry maintenance services can help.

Warning signs that your laundry equipment may be headed for a breakdown

Here are clues that your laundry equipment is due for maintenance and how laundry maintenance services can help.

As the commercial laundry industry is rapidly expanding in Australia, commercial linen rental owners need to introduce measures that would facilitate the smooth functioning of these linen services.

Disruptions in these services, like the sudden malfunctioning of some of the laundry equipment, such as washing machines, can hinder productivity and incur costly repair expenses which are unprofitable for their cost centre.

According to Hipages, one of the leading business listing sites in Australia, the cost of repairing a washing machine that has developed some issues may range between $80 and $500. The most costly repairs will come in handy if the washing machine does not power on due to mechanical or electrical issues, ranging from $200 to $400.

To this end, linen managers should ensure that they get to service their equipment adequately so that they can avoid cases of downtime.

As the commercial laundry industry is rapidly expanding in Australia, commercial linen rental owners need to introduce measures that would facilitate the smooth functioning of these linen services.

Disruptions in these services, like the sudden malfunctioning of some of the laundry equipment, such as washing machines, can hinder productivity and incur costly repair expenses which are unprofitable for their cost centre.

According to Hipages, one of the leading business listing sites in Australia, the cost of repairing a washing machine that has developed some issues may range between $80 and $500. The most costly repairs will come in handy if the washing machine does not power on due to mechanical or electrical issues, ranging from $200 to $400.

To this end, linen managers should ensure that they get to service their equipment adequately so that they can avoid cases of downtime.

4 warning signs that your commercial laundry equipment is on the brink of a breakdown

Lack of proper maintenance:

It is also important to note that failure to conduct periodic maintenance, including cleaning, lubrication, calibration, and inspection, may shorten the lifespan of laundry equipment. Without regular attention, parts will degrade at a quicker pace and cause system failure.

Overloading or misuse:

Laundry equipment used in a manner not intended or being pushed beyond its capability will require replacement sooner than expected. Inherent problems such as overloading may result in straining of parts of the machine or may cause imbalance when the machine is in operation.

Age-related wear and tear:

In its life cycle, it is expected that the various parts of laundry equipment will degrade, resulting in a higher risk of failure. This includes belts, bearings, and seals. This pressure build-up, corrosion, and fatigue lead to problems like leakage and complete failure.

Exposure to environmental factors:

Washing machines and dryers that are often exposed to environmental conditions, such as very high temperatures, humidity, dust, and other harsh conditions, may experience wear and tear at a faster rate. Excessive humidity also causes quicker rust and corrosion.

To prevent your laundry equipment from failing or heading for a breakdown, it is highly recommended that you invest in a platform that specialises in laundry maintenance services. Let’s explore the benefits of utilising this platform to prevent laundry equipment breakdowns.

The benefits of investing in laundry maintenance services to prevent laundry equipment breakdowns

Minimised downtimes: Preventive maintenance helps avoid unexpected breakdowns that can disrupt operations.

Maximised equipment efficiency: Maintenance services can optimise equipment performance and efficiency.

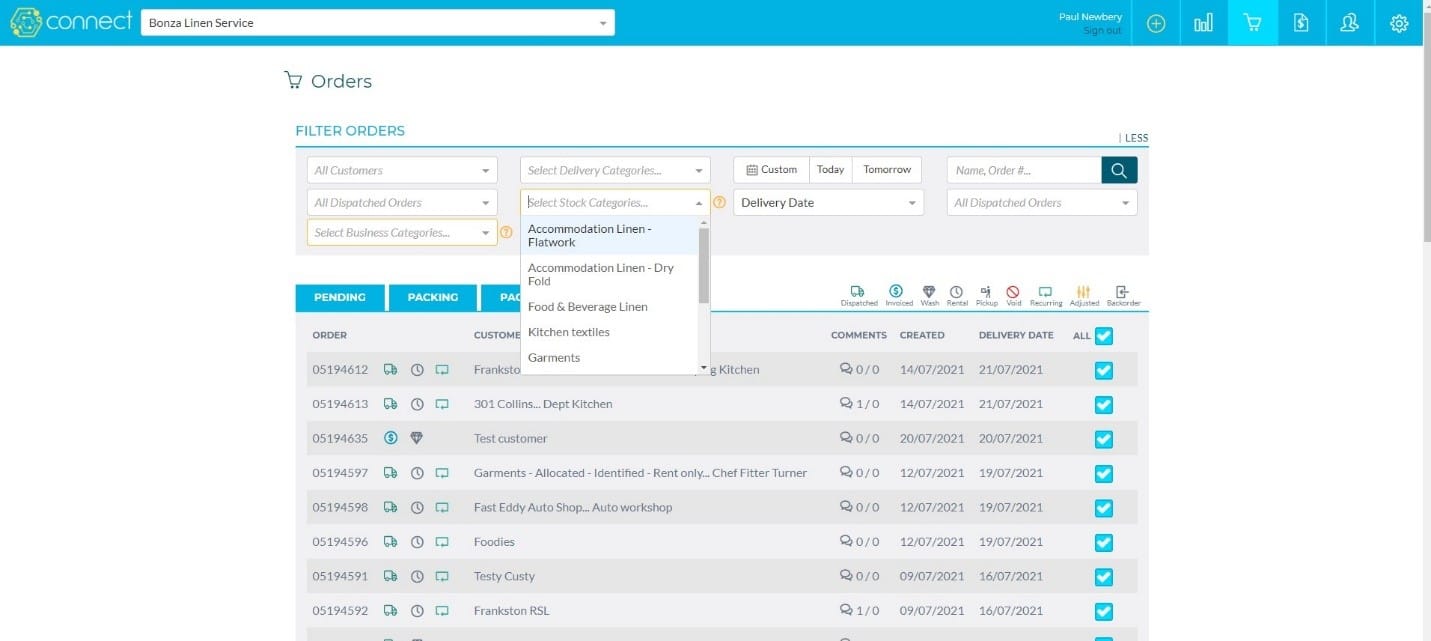

Full-time accessibility: Enjoy round-the-clock access to the software dashboard on your mobile, tablet, or PC.

Extended equipment lifespan: Preventive maintenance extends equipment lifespan and prevents major failures.

Boosted cost savings: Planned laundry maintenance is much more cost-effective than reactive repairs.

Tracked jobs: Never miss any issues with an outstanding maintenance job update of the laundry’s history.

Managed KPIs: Optimise operations and utilise linen much better with real-time performance monitoring.

Minimised downtimes: Preventive maintenance helps avoid unexpected breakdowns that can disrupt operations.

Maximised equipment efficiency: Maintenance services can optimise equipment performance and efficiency.

Full-time accessibility: Enjoy round-the-clock access to the software dashboard on your mobile, tablet, or PC.

Extended equipment lifespan: Preventive maintenance extends equipment lifespan and prevents major failures.

Boosted cost savings: Planned laundry maintenance is much more cost-effective than reactive repairs.

Tracked jobs: Never miss any issues with an outstanding maintenance job update of the laundry’s history.

Managed KPIs: Optimise operations and utilise linen much better with real-time performance monitoring.

Client success stories

"The transition to Bundle has been instrumental in Allied Laundry continuing to drive change and business improvement by providing real-time customer ordering information, streamlined ordering, and billing processes and have enabled a considerable reduction in staff time. The system has been a real success story for Allied Laundry."

Mark Mabbet

Allied Laundry Service

"No question is a stupid question in the eyes of the Bundle team. Their customer service, expertise and knowledge ensured a smooth transition for me when I purchased my business. The system is user friendly and easy to navigate, while syncing seamlessly with my accounts package."

Geraldine Minogue

Associated Laundry Services

Since the transition from a manual, paper-driven system to Bundle, the time spent managing orders through to invoicing has been reduced by some 75%. From an administrative perspective, it is far easier to track the progress of orders, respond to queries (and resupply dockets).

The management abilities for individual account needs with set days, recurring orders, fixing cut-off times, adding notes to orders and pick-ups means that all relevant persons have the same information.

Customer support is also given a high priority and queries and concerns are met promply and efficiently.

Cynthia Hertrick

Blueline Laundry

Book a demo

Ensure continuous productivity, minimise downtimes, and prevent costly repairs with laundry maintenance software.

Get in touch with us to book a demo.

FAQs

The frequency will depend on usage, but generally speaking, regular maintenance should ideally be done every 3-6 months.

Yes, most services cover both washers and dryers for comprehensive laundry equipment care.