Revolutionise your linen management with a laundry automation system

Unlock unprecedented efficiency and cost savings in your operations. Learn how cutting-edge automation technology is transforming linen management across multiple industries.

Revolutionise your linen management with a laundry automation system

Unlock unprecedented efficiency and cost savings in your operations. Learn how cutting-edge automation technology is transforming linen management across multiple industries.

For linen management companies serving diverse industries such as healthcare, hospitality, and manufacturing, staying competitive means embracing innovative solutions. That’s where a leading laundry automation system becomes useful. It’s a technology that’s changing how businesses handle their linen and textile needs.

These automation systems integrate advanced software, hardware, and data analytics to streamline every aspect of linen management. From sorting and washing to drying, folding, and distribution, these systems optimise each step of the process, resulting in significant time and cost savings.

As we delve deeper into the benefits of laundry automation, you’ll discover how this technology can transform your operations, boost productivity, and give your business a competitive edge in the volatile landscape of linen management.

For linen management companies serving diverse industries such as healthcare, hospitality, and manufacturing, staying competitive means embracing innovative solutions. That’s where a leading laundry automation system becomes useful. It’s a technology that’s changing how businesses handle their linen and textile needs.

These automation systems integrate advanced software, hardware, and data analytics to streamline every aspect of linen management. From sorting and washing to drying, folding, and distribution, these systems optimise each step of the process, resulting in significant time and cost savings.

As we delve deeper into the benefits of laundry automation, you’ll discover how this technology can transform your operations, boost productivity, and give your business a competitive edge in the volatile landscape of linen management.

Unleashing efficiency: How automation transforms linen management

Laundry automation systems are changing linen management across multiple industries, offering unparalleled benefits in efficiency, cost-effectiveness, and quality control. By integrating advanced technologies such as RFID tracking, intelligent sorting systems, and data analytics, these systems streamline operations from start to finish.

Let’s explore a few key ways in which automation can significantly enhance productivity and drive success for linen management companies serving diverse sectors.

Streamlined inventory management:

An automation system employs RFID technology to track each linen item throughout its lifecycle. This real-time tracking enables precise inventory management, eliminating guesswork and reducing overstocking or shortages. Linen management companies can optimise their stock levels, ensure timely replenishment, and minimise capital tied up in excess inventory. This streamlined approach not only improves cash flow but also enhances customer satisfaction by ensuring consistent availability of clean linens.

Enhanced sorting and processing efficiency:

Automated sorting systems use imaging technology and machine learning algorithms to classify linens based on fabric type, colour, and soil level. This eliminates manual sorting errors and speeds up the pre-wash process. By optimising wash loads and ensuring appropriate treatment for each linen type, the system maximises washing efficiency, reduces water and energy consumption, and extends textile lifespan. The result is a more streamlined operation with higher throughput and lower operational costs.

Optimised washing and drying cycles:

Automation systems utilise intelligent wash programming to determine the optimal wash cycle for each load based on fabric type, soil level, and required hygiene standards. This precision ensures thorough cleaning while minimising water and detergent usage. Similarly, automated drying systems adjust temperature and duration based on load characteristics, preventing over-drying and reducing energy consumption. These optimisations not only improve productivity but also contribute to sustainability efforts.

Data-driven decision making

Automation systems generate a wealth of data on every aspect of the operation, from wash cycle performance to linen lifespan. Analytics tools process this data to provide actionable insights, enabling managers to make informed decisions about process improvements, resource allocation, and maintenance schedules. By identifying bottlenecks, predicting equipment failures, and optimising workflows, companies can continuously enhance their productivity and operational efficiency across all industries.

As technology continues to evolve, the potential for further innovations in laundry automation is always growing. Forward-thinking linen management companies that embrace these systems position themselves at the forefront of the industry, ready to meet the challenges and opportunities of the future.

Bundle laundry asset management system

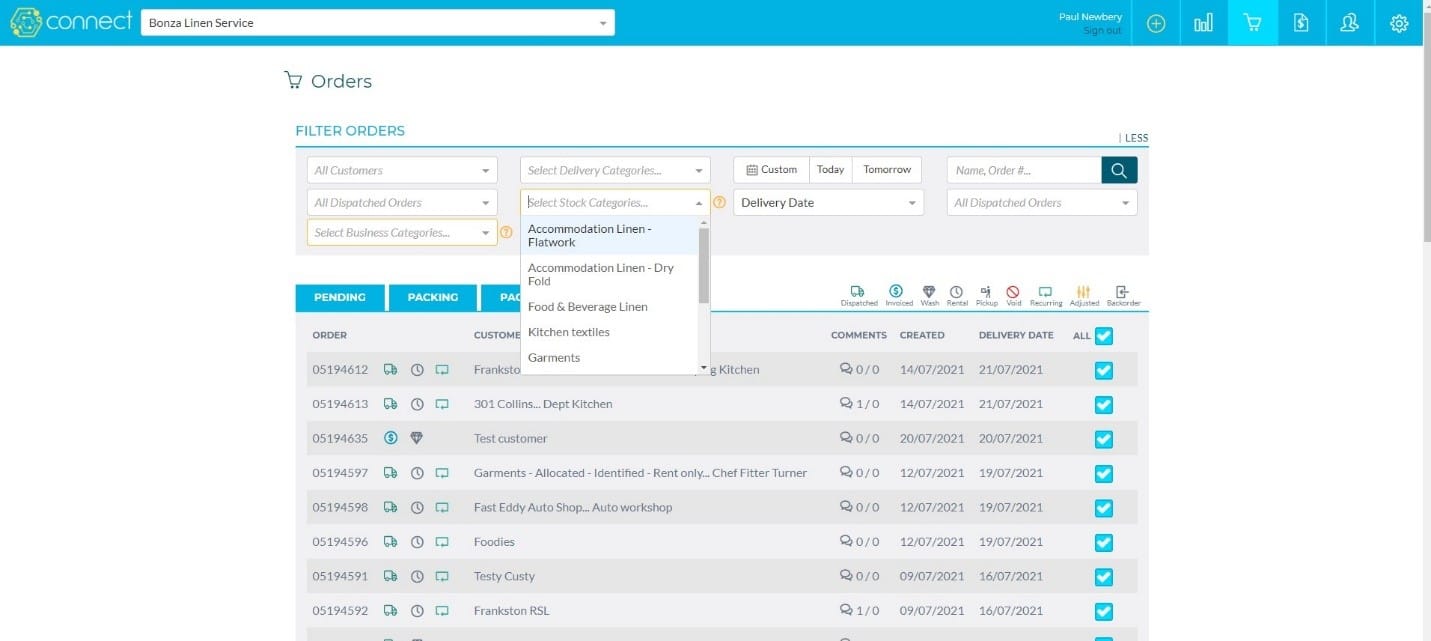

Bundle’s laundry management system is designed to meet the unique needs of linen management companies across diverse industries. Our comprehensive solution integrates seamlessly with your existing operations, providing end-to-end visibility and control over your linen inventory.

By partnering with Bundle, linen management companies can streamline their operations, reduce costs, and improve customer satisfaction. Our expert team provides ongoing support and training to ensure you maximise the benefits of your laundry automation system.

Bundle’s laundry management system is designed to meet the unique needs of linen management companies across diverse industries. Our comprehensive solution integrates seamlessly with your existing operations, providing end-to-end visibility and control over your linen inventory.

By partnering with Bundle, linen management companies can streamline their operations, reduce costs, and improve customer satisfaction. Our expert team provides ongoing support and training to ensure you maximise the benefits of your laundry automation system.

Client success stories

"The transition to Bundle has been instrumental in Allied Laundry continuing to drive change and business improvement by providing real-time customer ordering information, streamlined ordering, and billing processes and have enabled a considerable reduction in staff time. The system has been a real success story for Allied Laundry."

Mark Mabbet

Allied Laundry Service

"No question is a stupid question in the eyes of the Bundle team. Their customer service, expertise and knowledge ensured a smooth transition for me when I purchased my business. The system is user friendly and easy to navigate, while syncing seamlessly with my accounts package."

Geraldine Minogue

Associated Laundry Services

Since the transition from a manual, paper-driven system to Bundle, the time spent managing orders through to invoicing has been reduced by some 75%. From an administrative perspective, it is far easier to track the progress of orders, respond to queries (and resupply dockets).

The management abilities for individual account needs with set days, recurring orders, fixing cut-off times, adding notes to orders and pick-ups means that all relevant persons have the same information.

Customer support is also given a high priority and queries and concerns are met promply and efficiently.

Cynthia Hertrick

Blueline Laundry

Book a demo

Ready to level-up your linen management operations? Book a demo with our expert team to see firsthand how Bundle’s laundry automation system can boost your productivity and give you a competitive edge.

FAQs

RFID (Radio-Frequency Identification) tags are attached to individual linen items. These tags contain unique identifiers that can be read by RFID scanners throughout the laundry process. This allows for real-time tracking of each item, providing accurate inventory counts, wash cycle tracking, and loss prevention.

Many linen automation systems are designed to integrate with existing equipment. However, the level of integration can vary depending on the age and type of your current machinery. A thorough assessment of your current setup is usually conducted before implementation to determine the best integration strategy.